Model: Drucker-Prager

Overview

This model may be used to represent a solid material with plastic response to loading according to the Drucker-Prager yield criterion below:

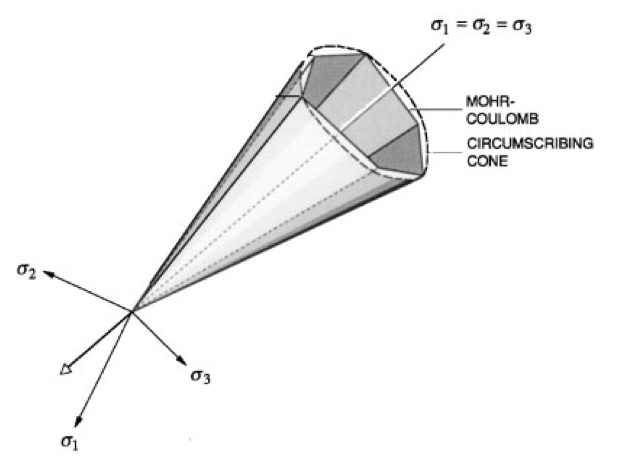

Fig. 86 Mohr-Coulomb and Drucker-Prager yield surfaces in principal stress axes (Borja, 2002).

The material behavior is linear elastic (see Model: Elastic Isotropic) for , and plastic for

.

The two material parameters

and

are derived by approximating the Mohr-Coulomb surface with a cone.

Figure 3 shows the Mohr-Coulomb yield surface and circumscribing Drucker-Prager surface in principal stress space.

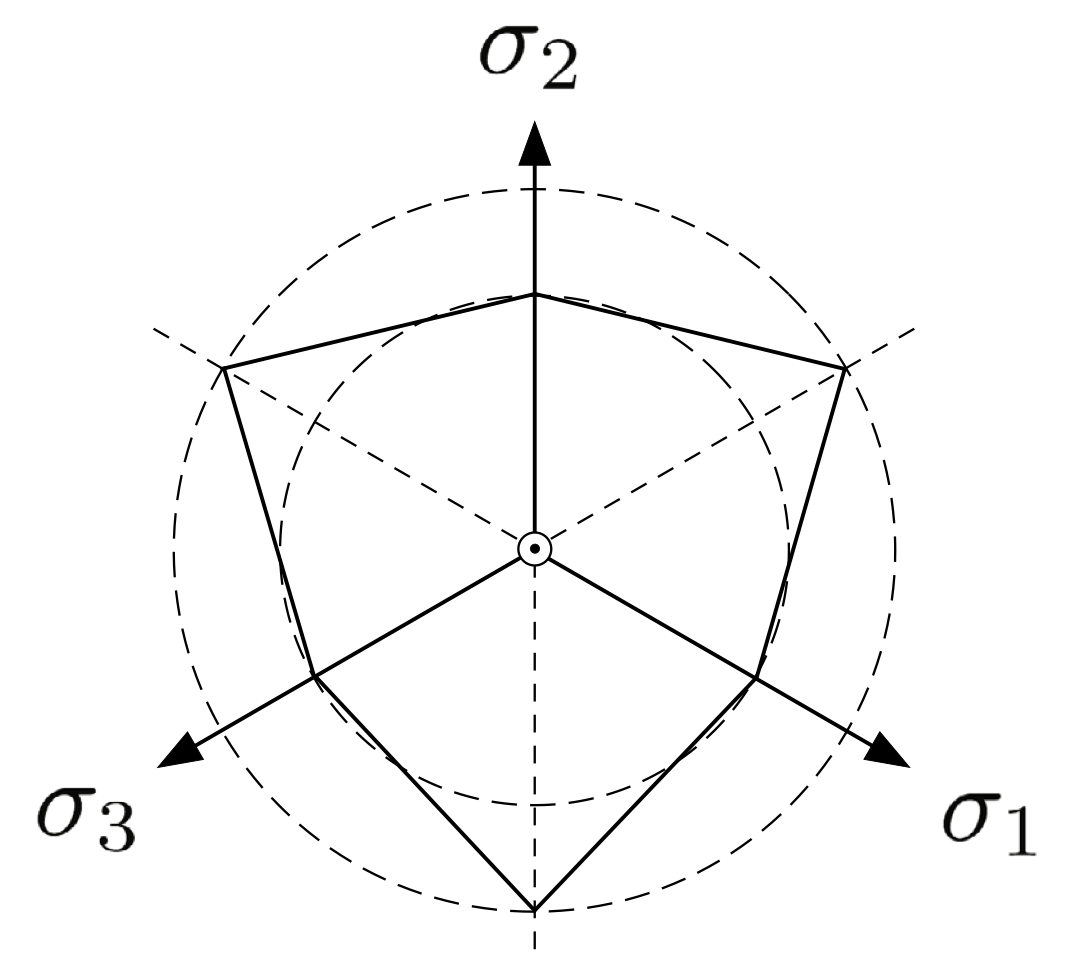

The Drucker-Prager yield surface has a circular cross-section in the deviatoric plane that passes through the tension or compression corners of the Mohr-Coulomb yield surface, as shown in the Figure 4.

The material parameters

and

are derived as:

where plus signs are for circles passing through the tension corners, and minus signs are for circles passing through compression corners.

Also, and

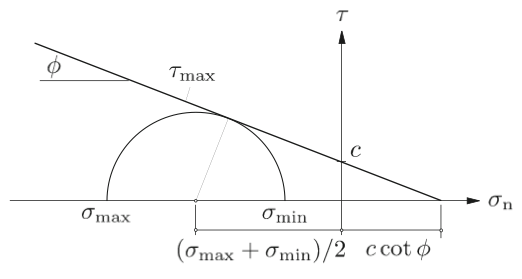

denote friction angle and cohesion, respectively, as defined by the Mohr-Coulomb failure envelope shown in Figure 5.

In GEOS, we use a compression corner fit (minus signs) to convert the user-specified friction angle and cohesion to

and

.

Fig. 87 Mohr-Coulomb and Drucker-Prager yield surfaces on the deviatoric plane (Borja, 2013).

Fig. 88 The Mohr-Coulomb failure envelope (Borja, 2013).

We consider a non-associative plastic potential to determine the direction of plastic flow.

where is the dilatancy parameter.

Setting

leads to associative flow rule, while for

non-associative flow is obtained.

The parameter

is related to dilation angle as:

where is the dilation angle.

If

, then the plastic flow is dilative.

Again, we use a compression corner fit (minus sign).

A hardening rule is defined which determines how the yield surface will change as a result of plastic deformations.

Here we use linear hardening for the cohesion parameter, ,

where is the hardening parameter.

A positive hardening parameter will allow the cohesion to grow, shifting the cohesion intercept vertically on the q-axis.

A negative hardening parameter will cause the cohesion to shrink, though negative cohesion values are not allowed.

Once all cohesion has been lost, the cohesion will remain at zero, so the cone vertex is fixed at the origin.

In either case, the friction and dilation angles remain constant.

See the DruckerPragerExtended model for an alternative version of hardening behavior.

Parameters

The following attributes are supported:

XML Element: DruckerPrager

Name |

Type |

Default |

Description |

|---|---|---|---|

defaultBulkModulus |

real64 |

-1 |

Default Bulk Modulus Parameter |

defaultCohesion |

real64 |

0 |

Initial cohesion |

defaultDensity |

real64 |

required |

Default Material Density |

defaultDilationAngle |

real64 |

30 |

Dilation angle (degrees) |

defaultDrainedLinearTEC |

real64 |

0 |

Default Linear Thermal Expansion Coefficient of the Solid Rock Frame |

defaultFrictionAngle |

real64 |

30 |

Friction angle (degrees) |

defaultHardeningRate |

real64 |

0 |

Cohesion hardening/softening rate |

defaultPoissonRatio |

real64 |

-1 |

Default Poisson’s Ratio |

defaultShearModulus |

real64 |

-1 |

Default Shear Modulus Parameter |

defaultYoungModulus |

real64 |

-1 |

Default Young’s Modulus |

name |

groupName |

required |

A name is required for any non-unique nodes |

Example

<Constitutive>

<DruckerPrager name="drucker"

defaultDensity="2700"

defaultBulkModulus="1000.0"

defaultShearModulus="1000.0"

defaultFrictionAngle="30.0"

defaultDilationAngle="20.0"

defaultHardeningRate="0.0"

defaultCohesion="10.0" />

</Constitutive>

Variant: J2 plasticity

J2 yield criterion can be obtained as a special case of the Drucker-Prager model by setting the friction and dilation angles to zero, i.e. .