Multiphase Flow with Wells¶

Context

In this example, we build on the concepts presented in Multiphase Flow to show how to set up a multiphase water injection problem with wells in the three-dimensional Egg model. The twelve wells (four producers and eight injectors) are placed according to the description of the original test case.

Objectives

In this example, we re-use many GEOSX features already presented in Multiphase Flow, but we now focus on:

- how to import an external mesh with embedded geological properties (permeability) in the GMSH format (

.msh), - how to set up the wells.

Input file

This example is based on the XML file located at

src/coreComponents/physicsSolvers/fluidFlow/benchmarks/Egg/dead_oil_egg.xml

The mesh file corresponding to the Egg model is stored in the GEOSXDATA repository. Therefore, you must first download the GEOSXDATA repository in the same folder as the GEOSX repository to run this test case.

Note

GEOSXDATA is a separate repository in which we store large mesh files in order to keep the main GEOSX repository lightweight.

The XML file considered here follows the typical structure of the GEOSX input files:

Coupling the flow solver with wells¶

In GEOSX, the simulation of reservoir flow with wells is set up by combining three solvers listed and parameterized in the Solvers XML block of the input file. We introduce separately a flow solver and a well solver acting on different regions of the domain—respectively, the reservoir region and the well regions. To drive the simulation and bind these single-physics solvers, we also specify a coupling solver between the reservoir flow solver and the well solver. This coupling of single-physics solvers is the generic approach used in GEOSX to define multiphysics problems. It is illustrated in Poromechanics for a poroelastic test case.

The three solvers employed in this example are:

- the single-physics reservoir flow solver, a solver of type CompositionalMultiphaseFVM named

compositionalMultiphaseFlow(more information on this solver at Compositional Multiphase Flow Solver),- the single-physics well solver, a solver of type CompositionalMultiphaseWell named

compositionalMultiphaseWell(more information on this solver at Compositional Multiphase Well Solver),- the coupling solver that binds the two single-physics solvers above, an object of type CompositionalMultiphaseReservoir named

coupledFlowAndWells.

The Solvers XML block is shown below.

The coupling solver points to the two single-physics solvers using the attributes

flowSolverName and wellSolverName.

These names can be chosen by the user and are not imposed by GEOSX.

The flow solver is applied to the reservoir and the well solver is applied to the wells,

as specified by their respective targetRegions attributes.

The simulation is fully coupled and driven by the coupled solver. Therefore, the time stepping

information (here, initialDt, but there may be other parameters used to fine-tune the time

stepping strategy), the nonlinear solver parameters, and the linear solver parameters must be

specified at the level of the coupling solver.

There is no need to specify these parameters at the level of the single-physics solvers.

Any solver information specified in the single-physics XML blocks will not be taken into account.

Note

It is worth repeating the logLevel="1" parameter at the level of the well solver to make sure that a notification is issued when the well control is switched (from rate control to BHP control, for instance).

Here, we instruct GEOSX to perform at most newtonMaxIter = "10" Newton iterations.

GEOSX will adjust the time step size as follows:

- if the Newton solver converges in

dtIncIterLimit x newtonMaxIter = 5iterations or fewer, GEOSX will double the time step size for the next time step, - if the Newton solver converges in

dtCutIterLimit x newtonMaxIter = 8iterations or more, GEOSX will reduce the time step size for the next time step by a factortimestepCutFactor = 0.1, - if the Newton solver fails to converge in

newtonMaxIter = 10, GEOSX will cut the time step size by a factortimestepCutFactor = 0.1and restart from the previous converged time step.

The maximum number of time step cuts is specified by the attribute maxTimeStepCuts.

Note that a backtracking line search can be activated by setting the attribute lineSearchAction to Attempt or Require.

If lineSearchAction = "Attempt", we accept the nonlinear iteration even if the line search does not reduce the residual norm.

If lineSearchAction = "Require", we cut the time step if the line search does not reduce the residual norm.

Note

To use the linear solver options of this example, you need to ensure that GEOSX is configured to use the Hypre linear solver package.

<Solvers>

<CompositionalMultiphaseReservoir

name="coupledFlowAndWells"

flowSolverName="compositionalMultiphaseFlow"

wellSolverName="compositionalMultiphaseWell"

logLevel="1"

initialDt="1e4"

targetRegions="{ reservoir, wellRegion1, wellRegion2, wellRegion3, wellRegion4, wellRegion5, wellRegion6, wellRegion7, wellRegion8, wellRegion9, wellRegion10, wellRegion11, wellRegion12 }">

<NonlinearSolverParameters

newtonTol="1.0e-4"

newtonMaxIter="25"

dtCutIterLimit="0.9"

dtIncIterLimit="0.6"

timestepCutFactor="0.1"

maxTimeStepCuts="10"

lineSearchAction="None"/>

<LinearSolverParameters

solverType="fgmres"

preconditionerType="mgr"

krylovTol="1e-4"

krylovAdaptiveTol="1"

krylovWeakestTol="1e-2"/>

</CompositionalMultiphaseReservoir>

<CompositionalMultiphaseFVM

name="compositionalMultiphaseFlow"

targetRegions="{ reservoir }"

discretization="fluidTPFA"

fluidNames="{ fluid }"

solidNames="{ rock }"

permeabilityNames="{ rockPerm }"

relPermNames="{ relperm }"

temperature="297.15"

maxCompFractionChange="0.3"

logLevel="1"

useMass="1"/>

<CompositionalMultiphaseWell

name="compositionalMultiphaseWell"

targetRegions="{ wellRegion1, wellRegion2, wellRegion3, wellRegion4, wellRegion5, wellRegion6, wellRegion7, wellRegion8, wellRegion9, wellRegion10, wellRegion11, wellRegion12 }"

fluidNames="{ fluid }"

relPermNames="{ relperm }"

wellTemperature="297.15"

maxCompFractionChange="0.5"

logLevel="1"

useMass="1">

<WellControls

name="wellControls1"

type="producer"

control="BHP"

referenceElevation="28"

targetBHP="3.9e7"

targetPhaseRate="1e6"

targetPhaseName="oil"/>

<WellControls

name="wellControls2"

type="producer"

control="BHP"

referenceElevation="28"

targetBHP="3.9e7"

targetPhaseRate="1e6"

targetPhaseName="oil"/>

Mesh definition and well geometry¶

In the presence of wells, the Mesh block of the XML input file includes two parts:

- a sub-block PAMELAMeshGenerator defining the reservoir mesh (see Tutorial 2: External Meshes for more on this),

- a collection of sub-blocks InternalWell defining the geometry of the wells.

The reservoir mesh is imported from a .msh file that contains the mesh geometry

and also includes the permeability values in the x, y, and z directions.

These quantities must be specified using the metric unit system, i.e., in meters

for the well geometry and square meters for the permeability field.

We note that the mesh file only contains the active cells, so there is no keyword

needed in the XML file to define them.

Each well is defined internally (i.e., not imported from a file) in a separate InternalWell

XML sub-block. An InternalWell sub-block must point to the reservoir mesh that the well perforates

using the attribute meshName, to the region corresponding to this well using the attribute

wellRegionName, and to the control of this well using the attribute wellControl.

Each block InternalWell must point to the reservoir mesh

(using the attribute meshName), the corresponding well region (using

the attribute wellRegionName), and the corresponding well control

(using the attribute wellControlName).

Each well is defined using a vertical polyline going through the seven layers of the mesh, with a perforation in each layer. The well placement implemented here follows the pattern of the original test case. The well geometry must be specified in meters.

The location of the perforations is found internally using the linear distance along the wellbore

from the top of the well, specified by the attribute distanceFromHead.

It is the responsibility of the user to make sure that there is a perforation in the bottom cell

of the well mesh otherwise an error will be thrown and the simulation will terminate.

For each perforation, the well transmissibility factors employed to compute the perforation rates are calculated

internally using the Peaceman formulation.

<Mesh>

<PAMELAMeshGenerator

name="mesh"

file="../../../../../../../GEOSXDATA/DataSets/Egg/egg.msh"

fieldsToImport="{ PERM }"

fieldNamesInGEOSX="{ rockPerm_permeability }"/>

<InternalWell

name="wellProducer1"

wellRegionName="wellRegion1"

wellControlsName="wellControls1"

meshName="mesh"

polylineNodeCoords="{ { 124, 340, 28 },

{ 124, 340, 0 } }"

polylineSegmentConn="{ { 0, 1 } }"

radius="0.1"

numElementsPerSegment="7">

<Perforation

name="producer1_perf1"

distanceFromHead="2"/>

<Perforation

name="producer1_perf2"

distanceFromHead="6"/>

<Perforation

name="producer1_perf3"

distanceFromHead="10"/>

<Perforation

name="producer1_perf4"

distanceFromHead="14"/>

<Perforation

name="producer1_perf5"

distanceFromHead="18"/>

<Perforation

name="producer1_perf6"

distanceFromHead="22"/>

<Perforation

name="producer1_perf7"

distanceFromHead="26"/>

</InternalWell>

<InternalWell

name="wellProducer2"

wellRegionName="wellRegion2"

wellControlsName="wellControls2"

meshName="mesh"

polylineNodeCoords="{ { 276, 316, 28 },

{ 276, 316, 0 } }"

polylineSegmentConn="{ { 0, 1 } }"

radius="0.1"

numElementsPerSegment="7">

<Perforation

name="producer2_perf1"

distanceFromHead="2"/>

<Perforation

name="producer2_perf2"

distanceFromHead="6"/>

<Perforation

name="producer2_perf3"

distanceFromHead="10"/>

<Perforation

name="producer2_perf4"

distanceFromHead="14"/>

<Perforation

name="producer2_perf5"

distanceFromHead="18"/>

<Perforation

name="producer2_perf6"

distanceFromHead="22"/>

<Perforation

name="producer2_perf7"

distanceFromHead="26"/>

</InternalWell>

Events¶

In the Events XML block, we specify four types of PeriodicEvents.

The periodic event named solverApplications notifies GEOSX that the

coupled solver coupledFlowAndWells has to be applied to its target

regions (here, reservoir and wells) at every time step.

The time stepping strategy has been fully defined in the CompositionalMultiphaseReservoir

coupling block using the initialDt attribute and the NonlinearSolverParameters

nested block.

We also define an output event instructing GEOSX to write out .vtk files at the time frequency specified

by the attribute timeFrequency.

Here, we choose to output the results using the VTK format (see Tutorial 2: External Meshes

for a example that uses the Silo output file format).

The target attribute must point to the VTK sub-block of the Outputs

block (defined at the end of the XML file) by name (here, vtkOutput).

We define the events involved in the collection and output of the well production rates following the procedure defined in Tasks Manager.

The time history collection events trigger the collection of the well rates at the desired frequency, while the time history output events trigger the output of the HDF5 files containing the time series.

These events point by name to the corresponding blocks of the Tasks and Outputs XML blocks, respectively. Here, these names are wellRateCollection1 and timeHistoryOutput1.

<Events

maxTime="1.5e7">

<PeriodicEvent

name="vtk"

timeFrequency="2e6"

target="/Outputs/vtkOutput"/>

<PeriodicEvent

name="timeHistoryOutput1"

timeFrequency="1.5e7"

target="/Outputs/timeHistoryOutput1"/>

<PeriodicEvent

name="timeHistoryOutput2"

timeFrequency="1.5e7"

target="/Outputs/timeHistoryOutput2"/>

<PeriodicEvent

name="timeHistoryOutput3"

timeFrequency="1.5e7"

target="/Outputs/timeHistoryOutput3"/>

<PeriodicEvent

name="timeHistoryOutput4"

timeFrequency="1.5e7"

target="/Outputs/timeHistoryOutput4"/>

<PeriodicEvent

name="solverApplications"

maxEventDt="5e5"

target="/Solvers/coupledFlowAndWells"/>

<PeriodicEvent

name="timeHistoryCollection1"

timeFrequency="1e6"

target="/Tasks/wellRateCollection1"/>

<PeriodicEvent

name="timeHistoryCollection2"

timeFrequency="1e6"

target="/Tasks/wellRateCollection2"/>

<PeriodicEvent

name="timeHistoryCollection3"

timeFrequency="1e6"

target="/Tasks/wellRateCollection3"/>

<PeriodicEvent

name="timeHistoryCollection4"

timeFrequency="1e6"

target="/Tasks/wellRateCollection4"/>

</Events>

Numerical methods¶

In the NumericalMethods XML block, we instruct GEOSX to use a TPFA finite-volume

numerical scheme.

This part is similar to the corresponding section of Multiphase Flow, and has been adapted to match the specifications of the Egg model.

<NumericalMethods>

<FiniteVolume>

<TwoPointFluxApproximation

name="fluidTPFA"

fieldName="pressure"

coefficientName="permeability"/>

</FiniteVolume>

</NumericalMethods>

Reservoir and well regions¶

In this section of the input file, we follow the procedure already described in Multiphase Flow for the definition of the reservoir region with multiphase constitutive models.

We associate a CellElementRegion named reservoir to the reservoir mesh.

Since we have imported a mesh with one region consisting of hexahedral cells, we

must set the attribute cellBlocks to DEFAULT_HEX.

Note

If you use a name that is not DEFAULT_HEX for this attribute, GEOSX will throw an error at the beginning of the simulation.

We also associate a WellElementRegion to each well. As the CellElementRegion,

it contains a materialList that must point (by name) to the constitutive models

defined in the Constitutive XML block.

<ElementRegions>

<CellElementRegion

name="reservoir"

cellBlocks="{ DEFAULT_HEX }"

materialList="{ fluid, rock, relperm, rockPerm, rockPorosity, nullSolid }"/>

<WellElementRegion

name="wellRegion1"

materialList="{ fluid, relperm }"/>

<WellElementRegion

name="wellRegion2"

materialList="{ fluid, relperm }"/>

Constitutive models¶

The CompositionalMultiphaseFVM physics solver relies on at least four types of constitutive models listed in the Constitutive XML block:

- a fluid model describing the thermodynamics behavior of the fluid mixture,

- a relative permeability model,

- a rock permeability model,

- a rock porosity model.

All the parameters must be provided using the SI unit system.

This part is identical to that of Multiphase Flow.

<Constitutive>

<DeadOilFluid

name="fluid"

phaseNames="{ oil, water }"

surfaceDensities="{ 848.9, 1025.2 }"

componentMolarWeight="{ 114e-3, 18e-3 }"

tableFiles="{ pvdo.txt, pvtw.txt }"/>

<BrooksCoreyRelativePermeability

name="relperm"

phaseNames="{ oil, water }"

phaseMinVolumeFraction="{ 0.1, 0.2 }"

phaseRelPermExponent="{ 4.0, 3.0 }"

phaseRelPermMaxValue="{ 0.8, 0.75 }"/>

<CompressibleSolidConstantPermeability

name="rock"

solidModelName="nullSolid"

porosityModelName="rockPorosity"

permeabilityModelName="rockPerm"/>

<NullModel

name="nullSolid"/>

<PressurePorosity

name="rockPorosity"

defaultReferencePorosity="0.2"

referencePressure="0.0"

compressibility="1.0e-13"/>

<ConstantPermeability

name="rockPerm"

permeabilityComponents="{ 1.0e-12, 1.0e-12, 1.0e-12 }"/>

</Constitutive>

Initial conditions¶

We are ready to specify the reservoir initial conditions of the problem in the FieldSpecifications XML block. The well variables do not have to be initialized here since they will be defined internally.

The formulation of the CompositionalMultiphaseFVM physics solver (documented

at Compositional Multiphase Flow Solver) requires the definition of the initial pressure field

and initial global component fractions.

We define here a uniform pressure field that does not satisfy the hydrostatic equilibrium,

but a hydrostatic initialization of the pressure field is possible using Functions:.

For the initialization of the global component fractions, we remind the user that their component

attribute (here, 0 or 1) is used to point to a specific entry of the phaseNames attribute

in the DeadOilFluid block.

Note that we also define the uniform porosity field here since it is not included in the mesh file imported by the PAMELAMeshGenerator.

<FieldSpecifications>

<FieldSpecification

name="initialPressure"

initialCondition="1"

setNames="{ all }"

objectPath="ElementRegions/reservoir/DEFAULT_HEX"

fieldName="pressure"

scale="4e7"/>

<FieldSpecification

name="initialComposition_oil"

initialCondition="1"

setNames="{ all }"

objectPath="ElementRegions/reservoir/DEFAULT_HEX"

fieldName="globalCompFraction"

component="0"

scale="0.9"/>

<FieldSpecification

name="initialComposition_water"

initialCondition="1"

setNames="{ all }"

objectPath="ElementRegions/reservoir/DEFAULT_HEX"

fieldName="globalCompFraction"

component="1"

scale="0.1"/>

</FieldSpecifications>

Outputs¶

In this section, we request an output of the results in VTK format and an output of the rates for each producing well. Note that the name defined here must match the name used in the Events XML block to define the output frequency.

<Outputs>

<VTK

name="vtkOutput"/>

<TimeHistory

name="timeHistoryOutput1"

sources="{ /Tasks/wellRateCollection1 }"

filename="wellRateHistory1"/>

<TimeHistory

name="timeHistoryOutput2"

sources="{ /Tasks/wellRateCollection2 }"

filename="wellRateHistory2"/>

<TimeHistory

name="timeHistoryOutput3"

sources="{ /Tasks/wellRateCollection3 }"

filename="wellRateHistory3"/>

<TimeHistory

name="timeHistoryOutput4"

sources="{ /Tasks/wellRateCollection4 }"

filename="wellRateHistory4"/>

</Outputs>

Tasks¶

In the Events block, we have defined four events requesting that a task periodically collects the rate for each producing well.

This task is defined here, in the PackCollection XML sub-block of the Tasks block.

The task contains the path to the object on which the field to collect is registered (here, a WellElementSubRegion) and the name of the field (here, wellElementMixtureConnectionRate).

The details of the history collection mechanism can be found in Tasks Manager.

<Tasks>

<PackCollection

name="wellRateCollection1"

objectPath="ElementRegions/wellRegion1/wellRegion1uniqueSubRegion"

fieldName="wellElementMixtureConnectionRate"/>

<PackCollection

name="wellRateCollection2"

objectPath="ElementRegions/wellRegion2/wellRegion2uniqueSubRegion"

fieldName="wellElementMixtureConnectionRate"/>

<PackCollection

name="wellRateCollection3"

objectPath="ElementRegions/wellRegion3/wellRegion3uniqueSubRegion"

fieldName="wellElementMixtureConnectionRate"/>

<PackCollection

name="wellRateCollection4"

objectPath="ElementRegions/wellRegion4/wellRegion4uniqueSubRegion"

fieldName="wellElementMixtureConnectionRate"/>

</Tasks>

All elements are now in place to run GEOSX.

Running GEOSX¶

The first few lines appearing to the console are indicating that the XML elements are read and registered correctly:

Adding Solver of type CompositionalMultiphaseReservoir, named coupledFlowAndWells

Adding Solver of type CompositionalMultiphaseFVM, named compositionalMultiphaseFlow

Adding Solver of type CompositionalMultiphaseWell, named compositionalMultiphaseWell

Adding Mesh: PAMELAMeshGenerator, mesh

Adding Mesh: InternalWell, wellProducer1

Adding Mesh: InternalWell, wellProducer2

Adding Mesh: InternalWell, wellProducer3

Adding Mesh: InternalWell, wellProducer4

Adding Mesh: InternalWell, wellInjector1

Adding Mesh: InternalWell, wellInjector2

Adding Mesh: InternalWell, wellInjector3

Adding Mesh: InternalWell, wellInjector4

Adding Mesh: InternalWell, wellInjector5

Adding Mesh: InternalWell, wellInjector6

Adding Mesh: InternalWell, wellInjector7

Adding Mesh: InternalWell, wellInjector8

Adding Event: PeriodicEvent, solverApplications

Adding Event: PeriodicEvent, vtk

Adding Output: VTK, vtkOutput

Adding Object CellElementRegion named reservoir from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion1 from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion2 from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion3 from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion4 from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion5 from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion6 from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion7 from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion8 from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion9 from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion10 from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion11 from ObjectManager::Catalog.

Adding Object WellElementRegion named wellRegion12 from ObjectManager::Catalog.

This is followed by the creation of the 18553 hexahedral cells of the imported mesh:

0 >>> **********************************************************************

0 >>> PAMELA Library Import tool

0 >>> **********************************************************************

0 >>> GMSH FORMAT IDENTIFIED

0 >>> *** Importing Gmsh mesh format...

0 >>> Reading nodes...

0 >>> Done0

0 >>> Reading elements...

0 >>> Reading element data...

0 >>> Number of nodes = 22227

0 >>> Number of triangles = 0

0 >>> Number of quadrilaterals = 0

0 >>> Number of tetrahedra = 0

0 >>> Number of hexahedra = 18553

0 >>> Number of pyramids = 0

0 >>> Number of prisms = 0

0 >>> *** Done

0 >>> *** Creating Polygons from Polyhedra...

0 >>> 59205 polygons have been created

0 >>> *** Done

0 >>> *** Perform partitioning...

0 >>> TRIVIAL partitioning...

0 >>> Ghost elements...

0 >>> Clean mesh...

0 >>> *** Done...

0 >>> Clean Adjacency...

0 >>> *** Done...

At this point, we are done with the case set-up and the code steps into the execution of the simulation itself:

Time: 0s, dt:10000s, Cycle: 0

Attempt: 0, NewtonIter: 0

( Rfluid ) = (9.39e+01) ; ( R ) = ( 1.06e+02 ) ;

Attempt: 0, NewtonIter: 1

( Rfluid ) = (2.14e+00) ; ( R ) = ( 2.20e+00 ) ;

Last LinSolve(iter,res) = ( 2, 3.62e-03 ) ;

Attempt: 0, NewtonIter: 2

( Rfluid ) = (3.23e-01) ; ( R ) = ( 3.37e-01 ) ;

Last LinSolve(iter,res) = ( 4, 1.82e-03 ) ;

Attempt: 0, NewtonIter: 3

( Rfluid ) = (1.07e-02) ; ( R ) = ( 1.16e-02 ) ;

Last LinSolve(iter,res) = ( 2, 6.13e-03 ) ;

Attempt: 0, NewtonIter: 4

( Rfluid ) = (7.46e-05) ; ( R ) = ( 7.50e-05 ) ;

Last LinSolve(iter,res) = ( 3, 5.09e-03 ) ;

coupledFlowAndWells: Newton solver converged in less than 15 iterations, time-step required will be doubled.

Visualization¶

A file compatible with Paraview is produced in this example. It is found in the output folder, and usually has the extension .pvd. More details about this file format can be found here. We can load this file into Paraview directly and visualize results:

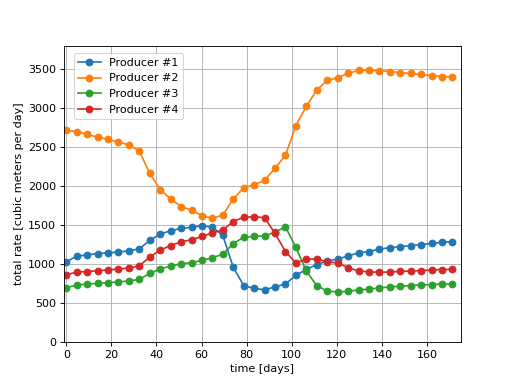

We have instructed GEOSX to output the time series of rates for each producer. The data contained in the corresponding hdf5 files can be extracted and plotted as shown below.

To go further¶

Feedback on this example

This concludes the example on setting up a Dead-Oil simulation in the Egg model. For any feedback on this example, please submit a GitHub issue on the project’s GitHub page.

For more details

- A complete description of the reservoir flow solver is found here: Compositional Multiphase Flow Solver.

- The well solver is description at Compositional Multiphase Well Solver.

- The available constitutive models are listed at Constitutive Models.